Our Services

Passivation

Passivation is a critical chemical process that significantly improves the corrosion resistance of stainless steel components by restoring its natural passive oxide layer. This protective film ensures long-term durability and performance.

We perform passivation in strict accordance with ASTM A967 and AMS 2700 standards, suitable for 300 and 400 series stainless steels and tailored to cleanliness and finish requirements.

Trusted by industries such as medical, aerospace, semiconductor, and food processing, our passivation process delivers contaminant-free, corrosion-resistant surfaces.

- Meets ASTM A967 and AMS 2700 specifications

- Compatible with stainless steel grades 300 and 400 series

- Common applications: surgical tools, instrumentation, cleanroom components

Electropolishing

Electropolishing enhances the surface finish of metal components by removing a microscopically thin layer. It smooths peaks, reduces surface roughness, and eliminates contaminants and microburrs.

Ideal for medical, semiconductor, pharmaceutical, aerospace, and food processing industries, it improves corrosion resistance, cleanability, and fatigue strength.

We meet ASTM B912 standards and offer custom finishes to meet your RA targets and surface quality needs.

- Removes embedded contaminants and sharp edges

- Improves fatigue life, corrosion resistance, and aesthetics

- Meets ASTM B912 and custom RA specs

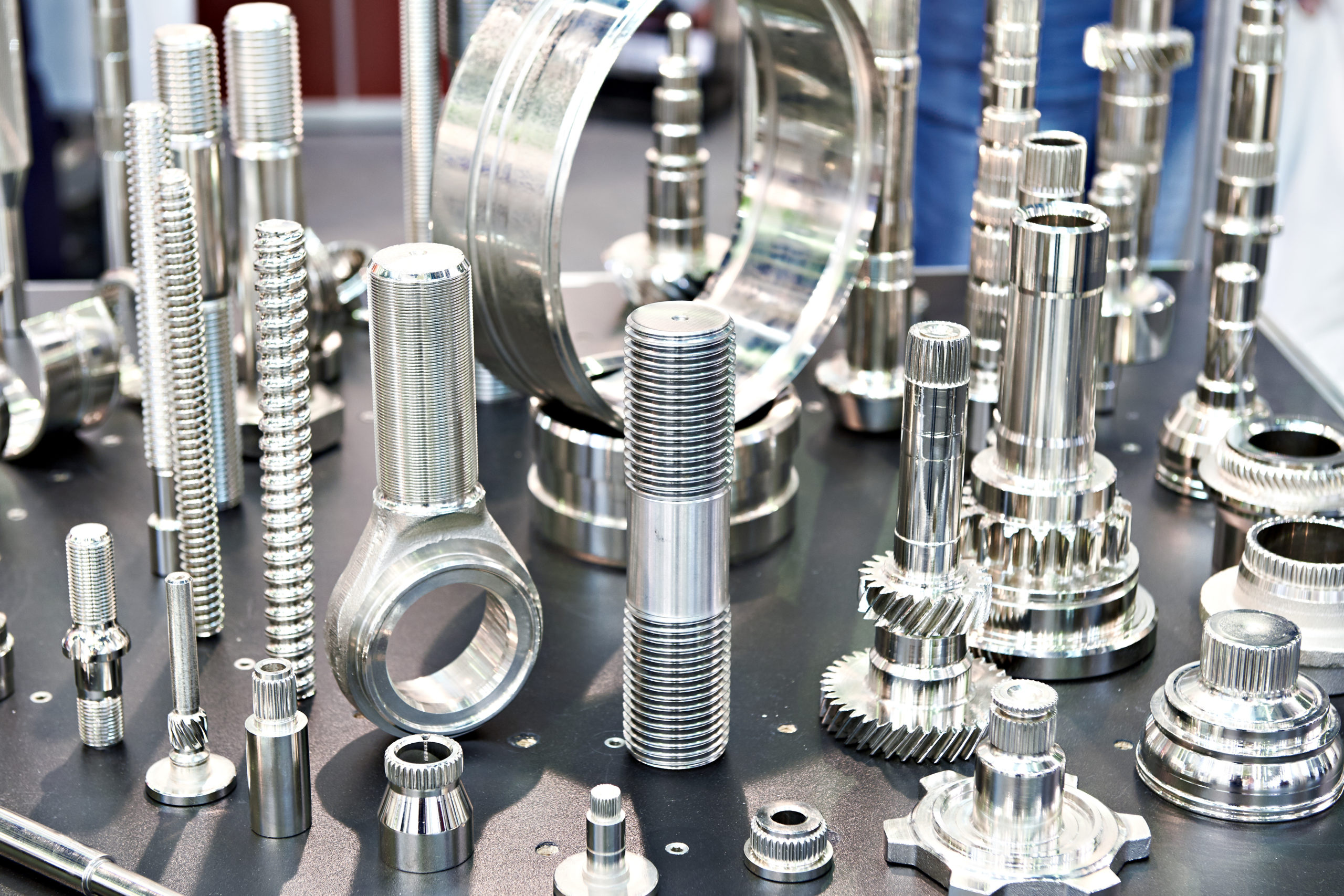

Gold, Silver, and Nickel Electroplating

Electroplating improves performance by applying a thin, durable layer of metal onto components. We offer nickel, gold, silver, tin plating, and more to enhance conductivity, corrosion resistance, and wear protection.

Our processes meet AMS, ASTM, MIL, and customer standards. Whether you're plating connectors, RF components, or fasteners—we ensure consistent, reliable results.

- Nickel, gold, silver, tin plating and more

- Electrolytic and electroless processes available

- Complies with AMS, ASTM, MIL, and customer specs

Custom Surface Finishing Solutions

We offer tailored surface finishing for specialized components and challenging requirements. Our team collaborates on prototypes, R&D, and production to meet compliance, biocompatibility, and material-specific goals.

We support a wide range of materials including stainless steel, titanium, aluminum, brass, copper, and exotic alloys, with full documentation and traceability to meet FDA, ISO, or custom standards.

- Non-standard finishing process development

- Masking, polishing, RA control, and custom cleaning

- Metals: stainless, titanium, copper, aluminum, and more