What is Passivation?

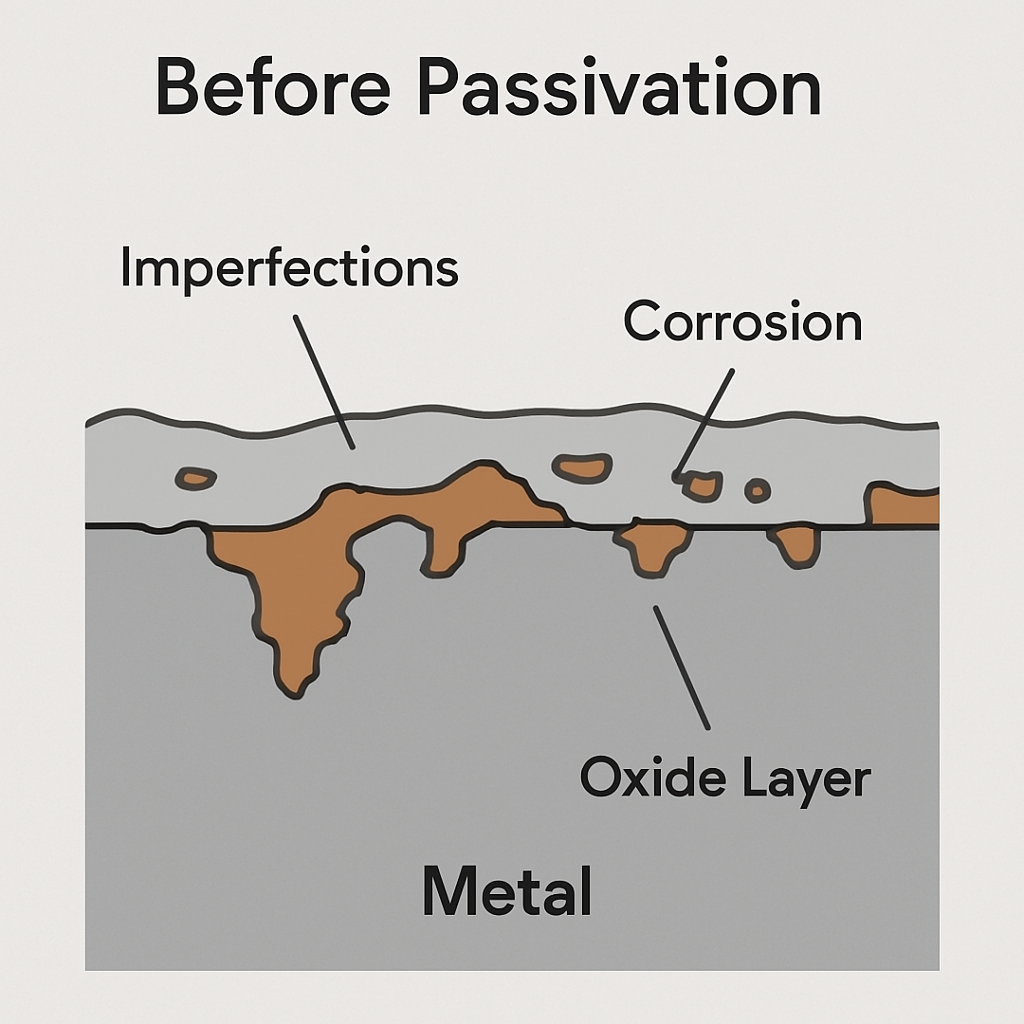

Before Passivation

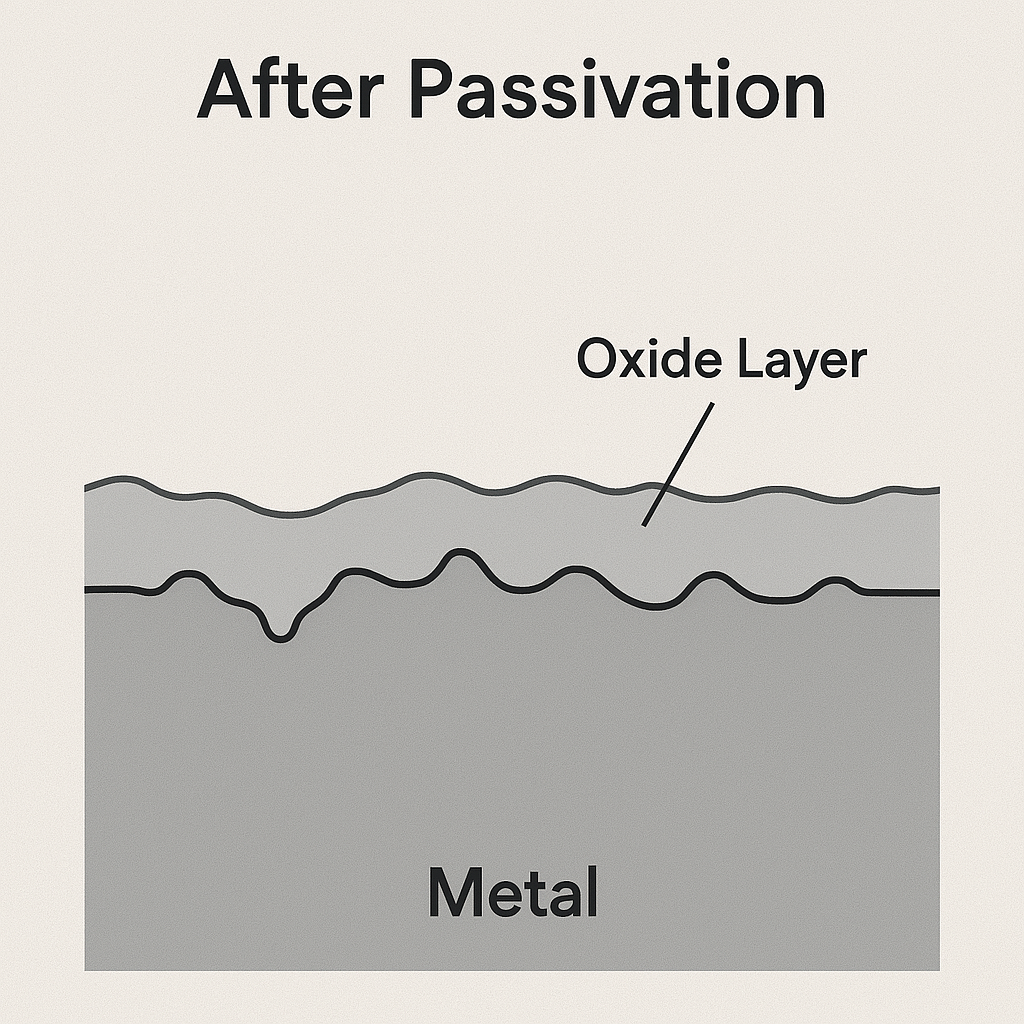

After Passivation

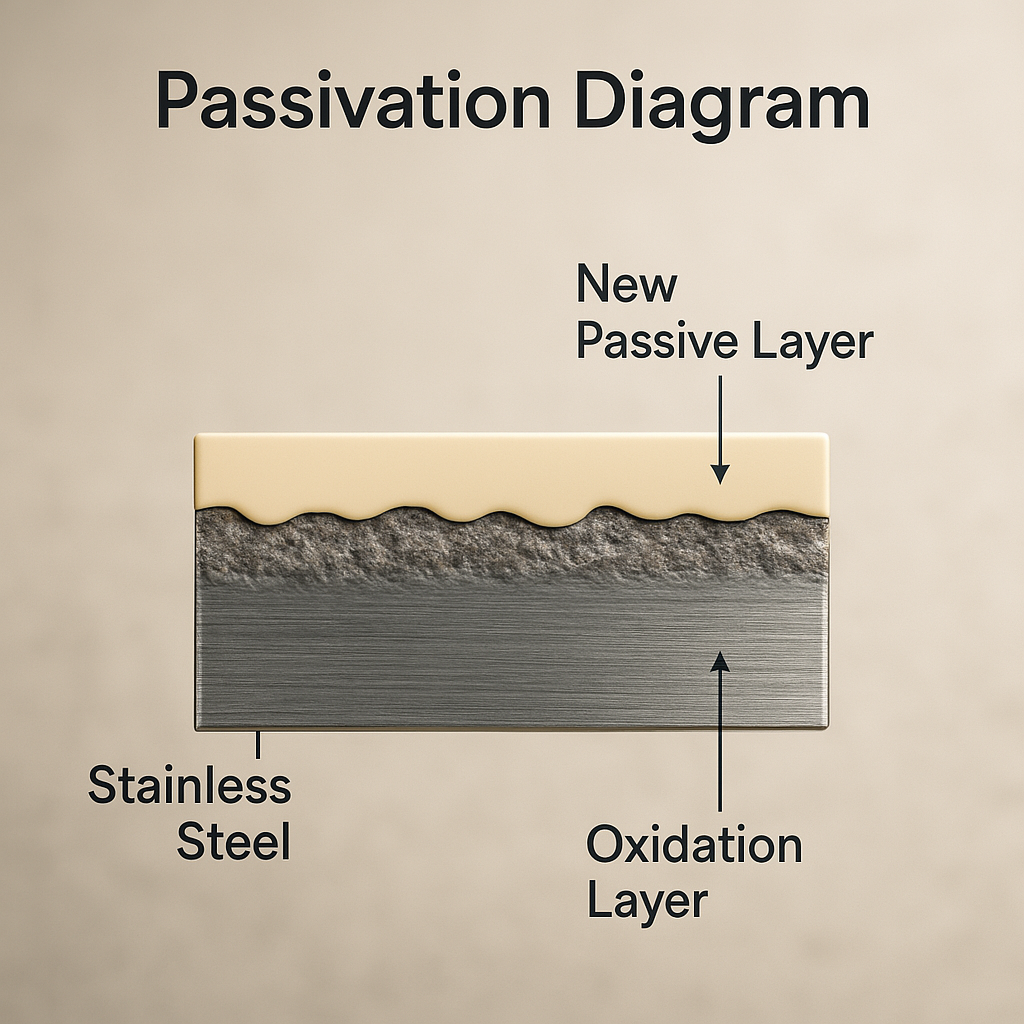

Passivation is a vital post-fabrication chemical treatment that improves the corrosion resistance of stainless steel by removing surface contaminants and creating a uniform, passive oxide layer. This process is especially critical in applications where metals are exposed to harsh or corrosive environments and where product reliability and safety are paramount.

Although stainless steel is naturally corrosion-resistant, microscopic iron particles or other foreign matter introduced during machining, welding, or handling can compromise its protective properties. Passivation eliminates these impurities and helps ensure long-term performance.

🔧 How the Passivation Process Works

- Initial Cleaning: Components are first cleaned using alkaline or solvent-based solutions to remove grease, oil, and debris.

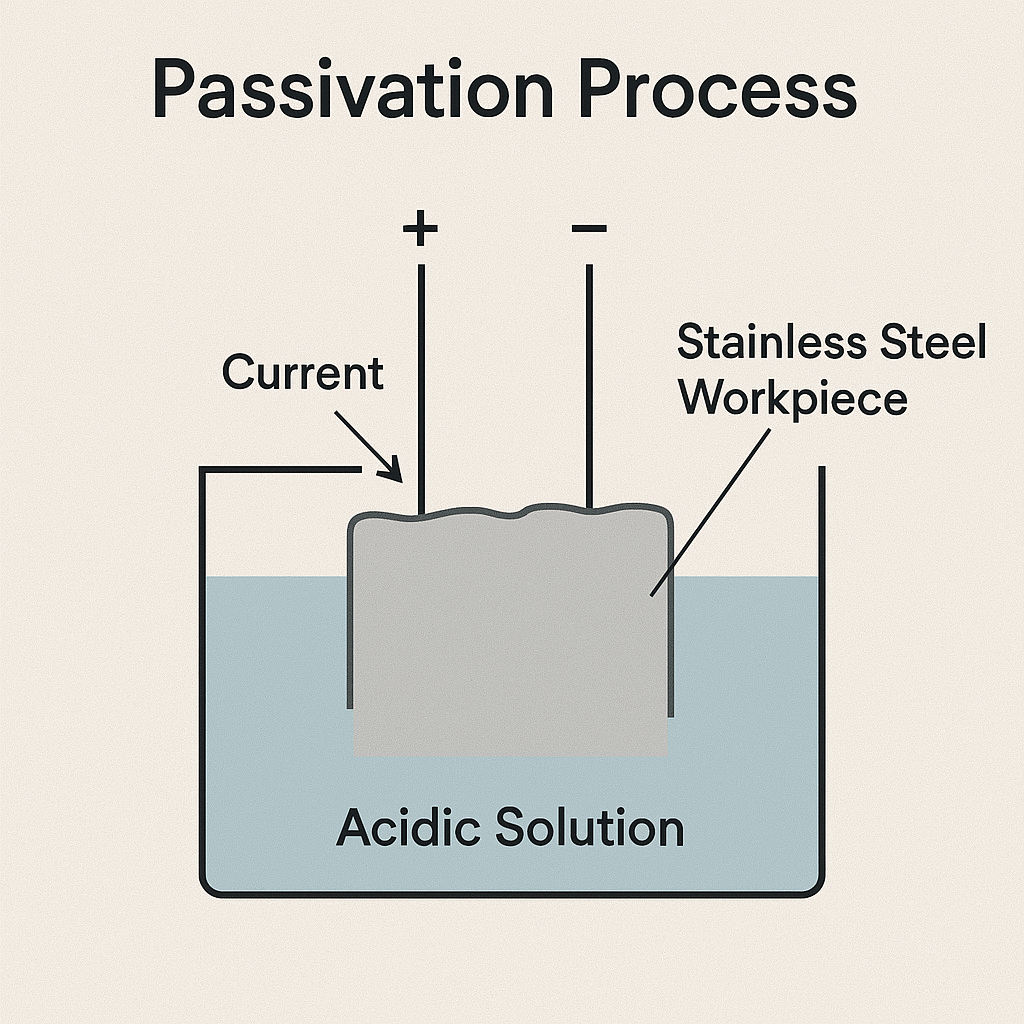

- Acid Bath: Parts are immersed in a nitric acid or citric acid solution, which dissolves any free iron or other contaminants from the surface.

- Oxide Layer Formation: The clean surface reacts with oxygen to form a protective chromium oxide film that passivates the surface.

- Rinsing and Drying: A final rinse with deionized water ensures no residues remain, followed by drying in a controlled environment.

💡 Why Passivation Matters

The passivation process provides several critical advantages:

- Enhances corrosion resistance by eliminating free iron and impurities

- Improves cleanliness and surface uniformity

- Reduces risk of product contamination in sensitive applications

- Helps meet stringent quality and compliance standards (e.g. ASTM A967, AMS 2700)

- Increases product durability, especially in marine, medical, and aerospace settings

📍 Applications & Industries

At American Metal Plating Company, we perform certified passivation for a variety of industries and applications where material integrity and compliance are critical:

- Medical & Surgical Instruments – to prevent contamination and ensure biocompatibility

- Aerospace & Defense – to maintain integrity in extreme environments

- Semiconductor & Cleanroom Manufacturing – to eliminate contamination risks

- Food Processing Equipment – to meet FDA and USDA hygiene standards

- Energy & Oilfield Components – to resist corrosion in harsh field conditions

✅ Standards & Compliance

AMPC provides passivation services in accordance with industry standards, including:

- ASTM A967: Standard for Chemical Passivation Treatments for Stainless Steel Parts

- AMS 2700: Aerospace Material Specification for Passivation of Corrosion-Resistant Steel

- FDA, RoHS, and REACH: Regulatory compliance for critical sectors

Get in Touch

Need certified passivation services or have technical questions? Our experienced team is here to help you select the right finishing process for your application.

Contact Us